Automated Coolant Management for Modern Manufacturing #

Efficient coolant management is essential for maintaining productivity and cost-effectiveness in today’s manufacturing environments. The SHUNT automatic coolant mixing and refill system offers a comprehensive solution, automating the replenishment and concentration adjustment of cutting fluids to eliminate manual errors and inefficiencies.

Addressing the Challenges of Manual Coolant Handling #

Manual replenishment of cutting fluids can lead to overfilling, increased costs, or underfilling, which results in low concentration and rapid fluid deterioration. The SHUNT system automates this process, ensuring accurate concentration levels and reducing the risks and expenses associated with manual intervention.

Integration with Industry 4.0 Initiatives #

As factories move toward greater automation, integrating all aspects of production—including coolant management—is crucial. The SHUNT system is designed to fit seamlessly into automated manufacturing environments, helping to remove bottlenecks caused by traditional fluid handling methods.

Advanced Filtration and Sterilization #

The SHUNT system purifies tap water through a multi-stage filtration process:

- Impurity Filtration: Initial removal of particulates using a PP fiber filter.

- Resin Filtration: Further purification to enhance water quality.

- Activated Carbon Filtration: Final stage to remove residual impurities and odors.

- Ozone Sterilization: Ensures the filtered water is free from microbial contamination before mixing.

Precision Mixing and Continuous Agitation #

A high-quality Italian-made oil-water mixer pump enables precise mixing of coolant concentrate with purified water, allowing for adjustable concentrations from 0% to 10%. The system also features a stirring device to keep the prepared cutting fluid in motion, preventing stagnation and maintaining consistency.

Smart Monitoring and Control #

The SHUNT system is equipped with advanced monitoring features:

- Oil Tank Level Meter: Detects low levels in 50-gallon barrels, ensuring timely refills.

- Flowmeter (Optional): Monitors flow rates with fixed and variable options.

- Concentration Meter (Optional): Uses refractive index detection to monitor coolant concentration, supporting a range of water-based solutions.

- Display Screen (Optional): QVGA 2.0 color LED display with status indicators, data storage via USB, and network support for IQ-Link.

- Level Detector (Optional): Japanese-made sensor with a detection range up to 1500mm.

System Specifications #

- Model: SHUNT

- Net Weight: 183 kg

- Dimensions (L x W x H): 900 x 1000 x 1610 mm

- Tank Capacity: Tap water: 125L / Mixer tank: 155L

- Filter Materials: PP fiber, resin, activated carbon

- Voltage: 220V AC, 50Hz

- Power Consumption: 500W/hr (continuous operation, indirect mode)

- Ozone Output: 500mg/hr

- Water Inflow: 10L/min

- Fluid Outflow: 40L/min or 80L/min (max)

- Oil-Water Mixer Pump Production: 0.17–50L/min (10–3000L/hr)

Enhancing Efficiency and Sustainability #

By automating coolant mixing and refill, the SHUNT system allows operators to focus on core production tasks, reducing labor costs and supporting ESG (Environmental, Social, and Governance) goals. This approach not only improves operational efficiency but also contributes to environmentally responsible manufacturing practices.

For more information or to discuss how the SHUNT system can benefit your facility, contact us.

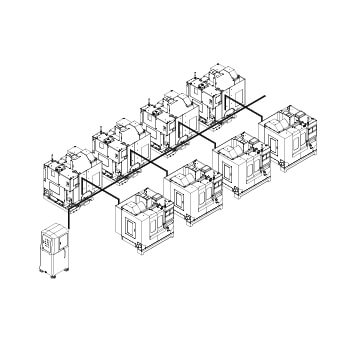

Product Images #