Innovative Sludge Separation for Modern Manufacturing #

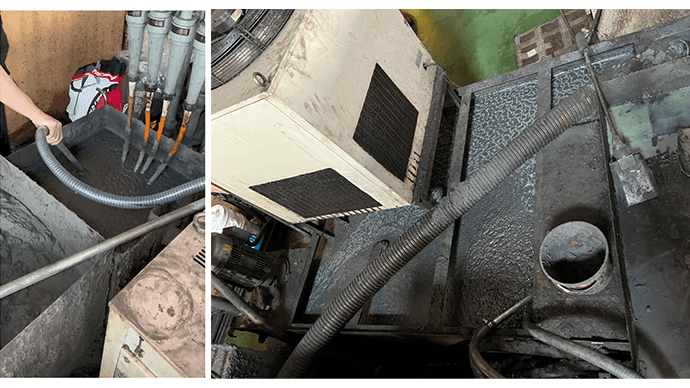

The FOODIE II Centrifugal Magnetic Filter by HC FENG is designed to address the challenges of sludge and particulate removal in precision machining environments. This advanced equipment streamlines the cleaning process, instantly extracting and discharging iron powder and dust without manual intervention. By supporting environmental sustainability and reducing operational costs, it aligns with ESG development goals and helps lower carbon tariffs.

Key Advantages of the FOODIE II Centrifugal Sludge Separator #

- High-Efficiency Magnetic Separation: Utilizes a 5000 Gauss magnetic field to filter particles down to 5 microns, effectively removing fine magnetic sludge such as cast iron powder.

- Minimized Downtime: Eliminates the need for CNC machine stoppages, reducing labor and coolant replacement frequency.

- Versatile Compatibility: Suitable for both neat oil and water-soluble coolants, making it adaptable to various industrial applications.

- Easy Implementation: Features a free-of-installation design for straightforward integration into any workspace.

Enhanced Filtration Workflow #

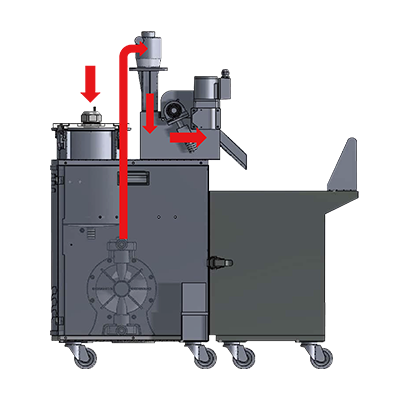

The FOODIE II operates through a multi-stage filtration process:

- Front Coarse Filter: With a 5.5L capacity, this stage intercepts large particulates like metal chips.

- Vortex Dynamic Filter: Removes up to 90% of 10μm particles in water-soluble cutting fluid and 80% in oil-based cutting fluid. The cyclone effect eliminates the need for filter core replacement, reducing consumable material usage and preventing air bubble formation.

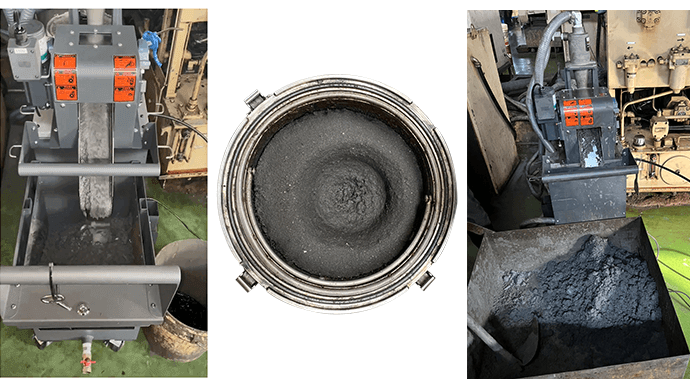

- Magnetic Separator: A power-driven roller generates a magnetic field up to 5,000 Gauss, efficiently separating magnetic metals such as iron from large quantities of powder or particles. This design is ideal for high-flow, highly magnetic separation.

- Sludge Cart (Optional): Separated sludge is discharged directly into the cart, which dries the sludge and collects residual coolant for recycling and reuse.

Step-by-Step Procedures #

- Chips and sludge are drawn in through the inlet pipe.

- Large particulates are retained in the front filter.

- Finer particulates pass into the vortex dynamic filter.

- Sludge is filtered and delivered to the magnetic separator.

- The magnetic separator discharges the extracted sludge.

- Clean coolant returns to the tank.

Installation and Maintenance #

- Installation: The centrifugal magnetic separator is fully assembled and installed prior to delivery. Simply unpack, connect the power, and activate the system.

- Maintenance: Regular cleaning of sludge residues around the roller is recommended. The equipment features an openable front door for convenient access and maintenance.

Technical Specifications #

| Model | FOODIE II |

|---|---|

| Machine Size | 750 x 600 x 1250 mm |

| Filter Capacity | 5.5 L |

| Net Weight | 77 kg |

| Max. Pump Capacity | 45 - 90 L/min |

| Air Pressure | 0.5 Bar - 8.3 Bar (7.25 Psi - 120 Psi) |

| Voltage | Single Phase 110V/220V, 60/50Hz |

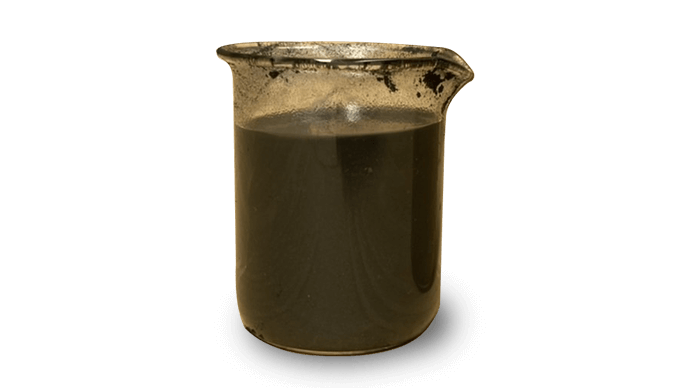

Before and After Results #

Applications in Precision Machining #

The FOODIE II centrifugal sludge separator is particularly suited for industries engaged in precision machining, especially those utilizing grinding machines that generate fine particulate sludge. Its robust design and efficient operation make it a valuable asset for any sector requiring reliable coolant purification and sludge removal, supporting both operational efficiency and sustainable manufacturing practices.

For further information, contact us or explore our case studies.