Comprehensive Guide to Metalworking Coolant Management and Solutions

Table of Contents

Understanding Metalworking Coolant Challenges and Solutions #

Cutting fluid, commonly used in machining processes, serves as both a coolant and lubricant. Its primary functions include rust prevention, cleaning, cooling, and lubrication, making it indispensable in cutting tool operations. However, during machining, various oils such as rust inhibitor oil, way lube oil, and other lubricants from equipment can mix with the coolant. This mixture forms a thick layer on the surface of the metalworking fluid, often referred to as tramp oil.

When tramp oil accumulates, the coolant tank becomes an ideal environment for anaerobic bacteria to thrive, leading to rapid fluid deterioration. Deteriorated coolant is characterized by unpleasant odors, rot, foam, and can cause skin allergies for operators. Over time, this not only affects the quality and lifespan of tools and workpieces but also impacts the overall efficiency and safety of the machining process.

Consequences of Rancid Coolant #

- Decreased machining quality and potential damage to lathe and milling equipment

- Reduced tool life and compromised processing efficiency

- Health risks for operators due to high bacterial content

- Increased downtime for cleaning and replacing coolant

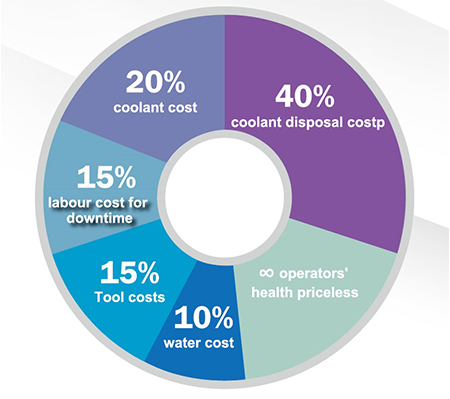

- Higher costs associated with frequent coolant replacement

- Environmental concerns from the disposal of contaminated coolant and wastewater

Advantages of Implementing HC Feng Equipment #

- Lower disposal costs for coolant oil

- Extended lifespan of metalworking fluids

- Reduced annual replacement expenses

- Decreased generation of wastewater and waste oil

- Enhanced tool life and improved machining quality

- Safer and healthier workplace conditions

- Contribution to global environmental sustainability

What Sets HC Feng Apart? #

- HC Feng was established by a dedicated team of engineers and technicians with extensive experience in addressing metalworking fluid challenges and developing advanced coolant oil separation and filtration systems.

- The Model Best-1 features a rest-time technique and an oil removal device, combining two separation methods for superior results with minimal water content.

- The Model Best-1 operates as a permanent, automatic coolant recycling system, equipped with a control panel and pH monitoring device.

- The Model Foodie functions as a robust, immediate sump cleaner, capable of filtering both magnetic and non-magnetic chips, sludge, or swarf. It is suitable for both water-soluble and neat oils.

- All units are designed with zero consumables, reducing ongoing maintenance and operational costs.

- HC Feng prioritizes providing tailored solutions for metalworking fluid and coolant oil issues, engaging with clients to address specific challenges. If a solution is not suitable, transparency is maintained.

- The company is committed to reliable quality, efficient and timely delivery, and comprehensive after-sales support, fostering strong relationships with customers worldwide.