Diverse Industry Applications for Coolant and Filtration Technologies #

Modern manufacturing and machining industries demand high standards of precision, efficiency, and sustainability. The following sectors benefit significantly from advanced coolant purification, filtration, and recycling solutions:

Application Industries #

Aerospace

Aerospace

Automotive

Automotive

Machining Tool Industry

Machining Tool Industry

Wastewater Recycling

Wastewater Recycling

Medical Parts

Medical Parts

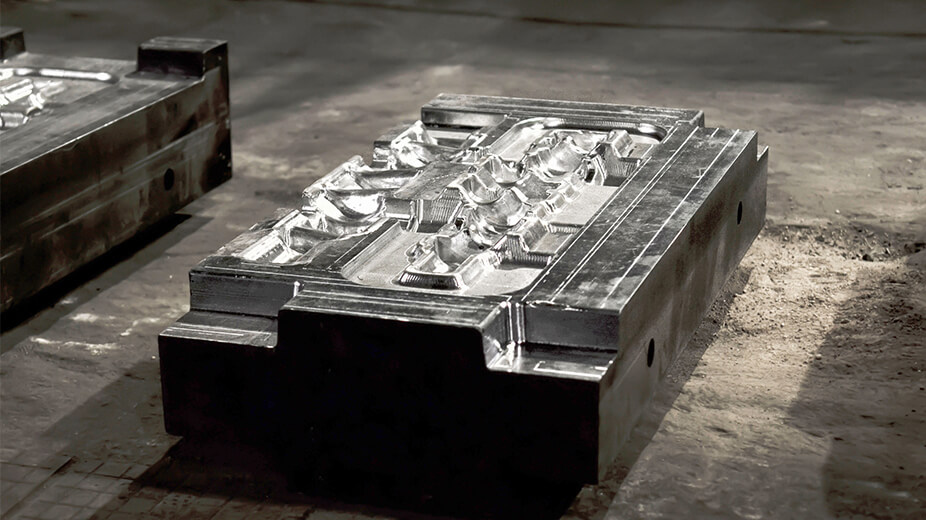

Die Casting

Die Casting

Bicycle parts

Bicycle parts

Gym Equipment

Gym Equipment

Aerospace #

Machining operations in the aerospace sector face some of the most demanding challenges. Strict industry standards leave no room for error, making equipment consistency and coolant quality critical. Reliable coolant management is essential for maintaining precision and meeting rigorous requirements. Learn more

Automotive #

The automotive industry is rapidly evolving, with a shift toward electric vehicles and increased automation. Manufacturers are focusing on the maintenance of machining tools and centers, as well as the environmental impact of coolants and lubricants. Sustainable coolant management supports both productivity and green manufacturing goals. Learn more

Machining Tool Industry #

High-quality machining relies on contaminant-free coolants. Proper coolant maintenance extends tool life, prevents operational issues, and ensures consistent product quality. Various filtration systems are available to purify and regenerate cooling fluids, supporting efficient and reliable manufacturing. Learn more

Wastewater Recycling #

Machining processes such as cutting, grinding, drilling, turning, and milling depend on effective cutting fluids for cooling, cleaning, rust prevention, and lubrication. Efficient recycling and purification of these fluids are vital for productivity and environmental responsibility. Learn more

Medical Parts #

The medical manufacturing sector has faced significant changes, especially since the COVID-19 pandemic. High demand for precision and zero tolerance for errors define this industry. Reliable coolant and filtration systems help manufacturers meet stringent quality standards despite supply chain and labor challenges. Learn more

Die Casting #

Die casting involves injecting molten metal into molds under high pressure, commonly used for producing auto parts, bicycle components, and vehicle lights. This process is efficient and allows for significant recycling of scrap materials, making it a popular and sustainable metalworking method. Learn more

Bicycle Parts #

Taiwan-made bicycles and components are renowned for their accuracy, performance, and durability. Local manufacturers consistently meet the high expectations of cycling enthusiasts worldwide, supported by advanced machining and coolant management solutions. Learn more

Gym Equipment #

Producers of fitness and gym equipment face intense competition, requiring them to deliver high-quality metal parts at competitive prices and with reliable service. Efficient manufacturing processes, including effective coolant and filtration systems, are key to meeting market demands. Learn more